Table of Contents

In the last few years, kitchen DIYs have gotten very popular. They don’t have to be over the top and they also don’t have to break your wallet. If you’re looking to add a cheap way to get some solid countertops then you’re reading the right blog. Check out my countertop plans and follow along!

Materials I Used to Build the Countertop

Step 1: Moving Material to the Shop and Cutting Edges

The first thing I did was move my mobile cart to the side of my miter saw stand. This is so I can flip out the wing and pull material directly from the cart to the saw and cut the ends. Whenever you’re joining boards together you need all the edges and ends to be at a 90 and straight. The miter takes care of all the ends. It’s also at this step that you can cut your boards to length. I recommend taking the measurement your top needs to be then leaving yourself and extra 1” or 2. You will cut it down perfectly later on.

Step 2: Rounding The Edges of the Material

Next is to knock off the rounded edges of the material. If you have a jointer, then you can use it to get one edge flat…..and one face flat. Next I move the pretty large pile to my table saw. Here I make sure to place the jointed edge up against the tablesaw fence to get the second edge parallel. Then I use the thickness planer to get the second face flat.

Now if you don’t have a jointer then I’ll leave you a link to two videos I’ve done where I show how to use a table saw or a router as a jointer. But you can definitely keep this project simple and let it be a little imperfect. If you only have a tablesaw, you can use it to cut off each rounded edge, then leave the face alone. This method will require more sanding and you might end up with a few small gaps, but you can still build yourself some countertops.

Step 3: Creating the Countertop Pattern

Ok after getting all the material square and straight, I next laid out my boards to get the depth my countertop and shelf needed then started rearranging them. The first thing I do is line up one side of the boards to be in line with one another. Now my finished countertop will land about here but it’s aways best to make a bigger than needed slab then cut it down in the end.

Next I look at the tree ring direction and try to stagger them. See how these rings curve down? This one is pretty center but this one curves up, this one down, What you want you avoid is all the rings facing the same direction as that will promote the entire slab to cup in that direction whereas alternating them will oppose forces.

The next thing I look at is where all the seams line up, see how most all land right in this zone? I want a little more variety so what you can do is take smaller boards and place them at the front. Just flip flop the two boards and that will push the seam away from the others. To where after I did that with a few other rows, now my seams were spaced out all across the slab.

Ok then last thing I looked at before sticking things together, was the butt joints. You can see this joint doesn’t close nicely. If it doesn’t close nicely now, it definitely won’t one you put glue on it so take the time to re cut both ends here at the miter saw.

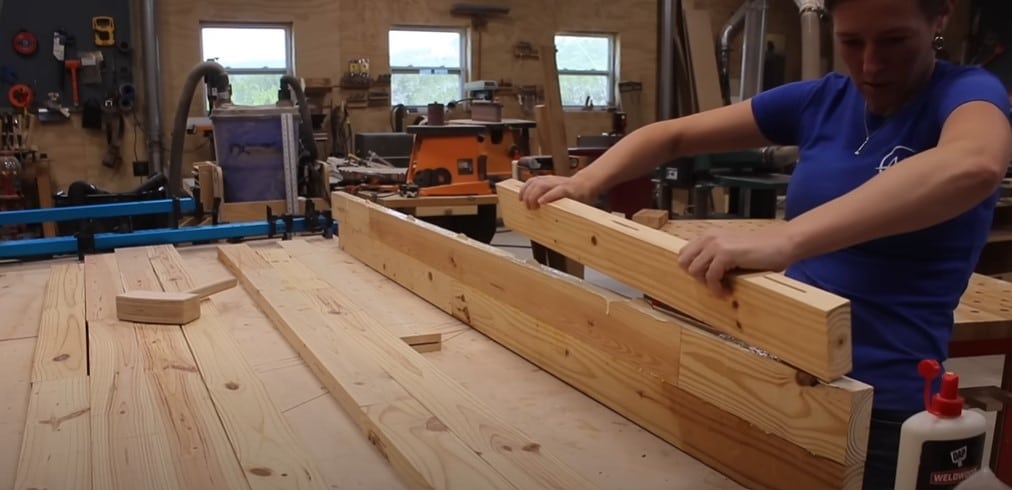

Step 4: Assembling the Countertop

Ok now lets do the thing that I would bet causes the most stress in woodworking. I’m talking about glue up! It is common when you’re first starting to build to make a big slab like this and try to glue up all the boards at one time. However, you learn really quick that it’s way better to do multiple small glue ups so they come out right rather than rush it and mess it up or stress yourself out.

When you’re glueing things together with yellow wood glue, my go to is DAPS Weldwood, you typically have about 3-4 mins of working time, which is not a lot. So have as many things ready to go as you can such as clamps, brushes, mallets, and bisquets in my case. Which lets talk about next. You can definitely cut all your boards and just glue then clamp them together but where bisquets help is with aligning the tops.

Once you apply glue to two surfaces they will slip and slide and getting a perfectly flush top is almost impossible. By cutting in bisquets slots…. this tool references the top of each board to cut in a slot on each edge so that when you insert a biscuit, it will automatically align each board and not allow it to slip around while applying pressure. Alternatives that achieve the same thing are dowels or a domino but remember you can definitely just glue up the boards if you don’t have anything, it will just require more flattening in the next step.

Step 5: Altering the Countertop Thickness (optional)

Actually, I added in a step. See after milling my boards, my 2x4s turned out to be only 1 1/4” thick. Which is good but I personally wanted the look to be closer to 2”. To achieve this, I cut a nose that is the thickness I want and simply attached it to the very front. So know this is a trick you can use to make your glue up look thicker.

Step 6: Thinning out the Countertop

Ok, now lets flattening this thing. Like everything in building, there are several ways to do everything. The countertop is too wide for my thickness planer so I just did this by hand with my 4” belt sander. You want to choose the widest belt sander you have so it’s easier to keep it flat and not create divots. I also like to turn my sander to a 45 in the first pass to hog away material faster, then I sand out the scuffs this creates in the lower grits. For my skinner matching shelf, I threw this through the drum sander and this makes quick work of it.

Step 7: Cutting the Countertop to Length

I now cut my top and shelf to their exact needed length. I chose the sliding portion of my tablesaw to make sure this cut was at a perfect 90 but a track saw or circular saw with a fence would work as well. Next I wanted to set the countertop in place and see how it was going to look up against my wall. No wall is ever perfectly straight so expect to have some gaps on your install.

You can cover up this gap with a backsplash board or you can trace the exact shape of your wall onto the countertop, this is called scribing. I did this with a washer but you can use just about anything. Once I had my line established I used my sander once again to take away material up to it. If you have a big gap you can always use something like a multi tool to cut away more material up front then refine it with a sander.

Step 8: Applying Finish

Ok and that’s it for the technique building part, I now have a countertop ready to install but before doing that I finished it. I’m using Total Boat’s Gleam 2.0 which is a Spar Varnish that is super easy to use, a high gloss (exactly what I was going for here), and my favorite feature: it’s fast drying. I like to use their Wood Sealer varnish primer before hand which fills in the grain to create a smoother finish.

Finishing Tip:

Have you ever seen white washed items before? Well I wanted a slight grey tint so I did the same thing where you can take latex paint and dilute it with water to create a more translucent stain sort of finish, but I did it with grey. The more water you add, the more translucent it will be. I used a foam brush to wipe it on, then almost immediately wiped it off. After letting that dry I applied a clear coat to protect everything.

Step 9: Installing the Countertop

To install the countertop I simply crawled inside and screwed through some wooden scrap strips I screwed into place…and you can see how taking the time to scribe the two edges really makes a difference. Then for the shelf up here I screwed a cleat to the corner where there is framing, then cut in a receiving notch so my shelf could sit on top and allow me something to screw down onto. The left terminates into the cabinets so I could go to the inside and go directly into the end grain.

Annnnd I’m going to call that another project done. I’ll leave you links to the videos showing you how to build cabinets and also me installing these in case you’re interested. I hope this video has given you some good tips or inspiration if making cheap countertops is on your to do.