Table of Contents

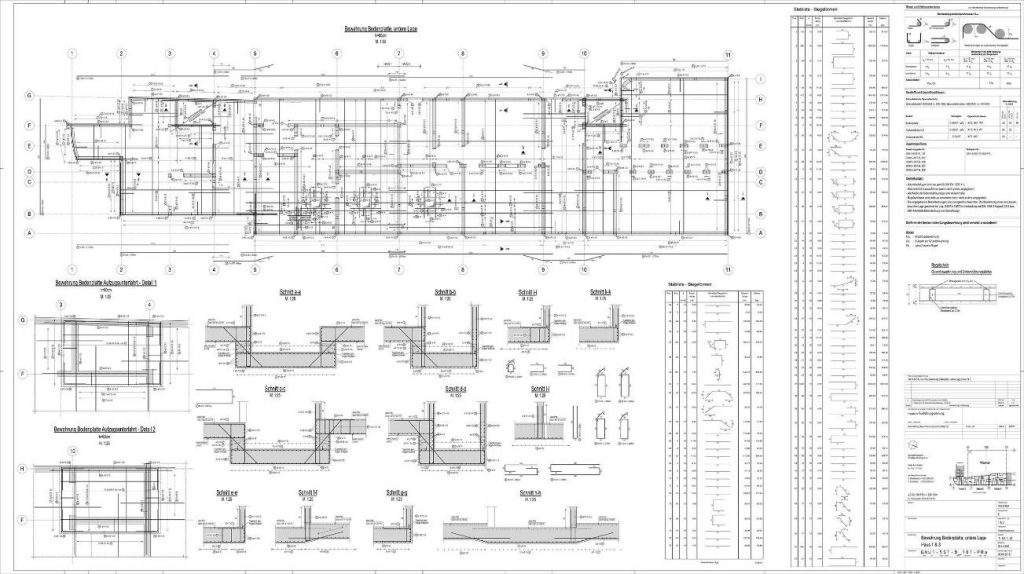

Rebar Placing on Structure Drilling Software rebar is a type of metal in the construction industry. It forms welded structures such as steel girders, columns, and pilings. Rebar is also used as a pre-fabricated formwork material (to construct precast concrete masonry units and wall sections) when construction projects require the erection of steel columns and rows of reinforced concrete walls with all their parts (including formwork). Consequently, in bending formwork methodologies, it plays an important role. Rebar placement software allows users to model, design, and produce rebar frames for any structure. The software enables the user to create a project model that has not yet been made. In other words, it allows the user to make decisions before construction begins on the new project. 3d rebar software drawing in the civil engineering field is a program used to calculate the number and size of rebar pieces required to support a structure. It performs complex calculations quickly, with simple user navigation. 3D rebar software drawing in civil engineering can be used to build various structures such as bridges, tunnels, buildings, and foundations.

Rebar is an indispensable part of a structure; its shape depends on the project requirements. If you work in civil engineering and need to place rebar, rebar placing software helps you. You don’t have to worry about the quality and its utility anymore because 3d rebar software helps use proper 3d drawing to understand better how it will be used. Regarding civil engineering and the rebar field, 3D rebar placing software is important. This software helps engineers and architects in their work by accurately calculating the size and shape of rebar parts. Rebars are beams that are used in steel structures. In civil engineering, rebar is a structural element that provides additional strength to concrete. Construction and structural engineers often use rebar as the central structural unit in any project.

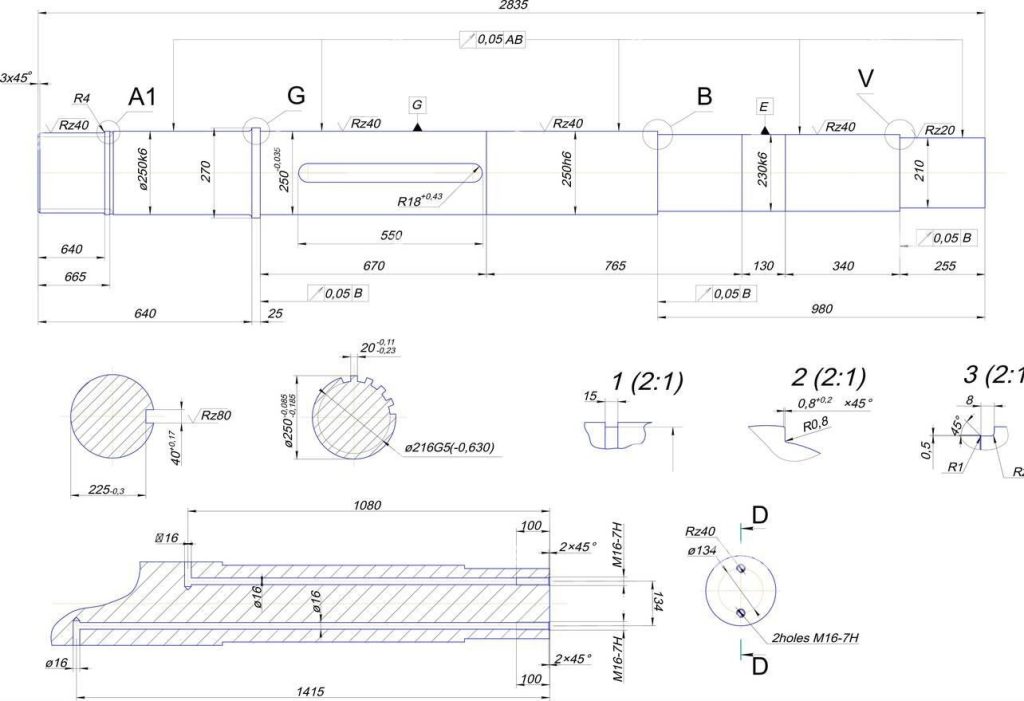

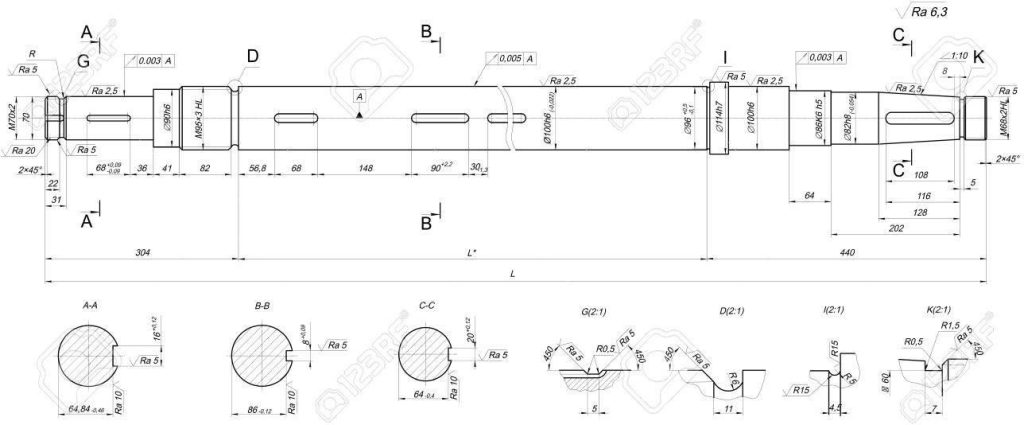

Shaft Drawing:

In most civil engineering fields, the actual drawing is the shaft drawing. It determines how each bearing will be supported and helps to identify and locate all the major joints in steel structures. Shaft drawing is one of the crucial tasks in civil engineering. It is also one of the essential things for a civil engineer to have good skills in this field. The main reason for doing this is to give an insight into the inner workings of the specific machinery and apparatus used in designing any structure. It ensures that everything is connected correctly, welded, and aligned to function properly. In civil engineering, shaft drawing determines the precise location and dimensions of the structural elements in a structural system, including their load-carrying capacities, such as a building’s footprint, exterior cladding, or floor system. Shaft drawing is vital to understand the number of steel bars required. It also gives a clear idea about the shank length, size, and gauge for fabrication. Why is shaft drawing better than another drawing method? Firstly it can stick on any surface, and some models have it as a built-in feature. Drawing can be done in any place or period, regardless of the weather or time of day. And the most important point is that this method is the most cost-friendly drawing technique because you can use existing models and manuals.

It’s a common misconception that shaft drawing is bad, but that’s not true. Shaft drawing can be used where the sound barrier is significant (engineers) or where there are multiple areas of concern (with multiple machine functions). Shaft drawing is also more accurate than other methods because it requires measuring and placing multiple reference lines, called guide blocks, precisely on the part for proper alignment. In addition, shaft drawing can be used when different parts need to be aligned, such as outer and inner diameter – this alignment method is called taper hole drawing. For the two diameters to align correctly, a single-line or centerline shaft drawing is required. Shaft drawing is a method of creating steel parts and structures. It is a process that uses the technique for forming, shaping, and joining components. In this process, the blank is rotated manually or by machine until the desired shape is obtained. Shaft drawing has many advantages compared to other methods, such as forging and stamping. Shaft drawing is the most popular method of drawing product shapes with a template in the metal stamping industry. Shaft-based drawing machines stamp the location and design of products on a piece of steel.

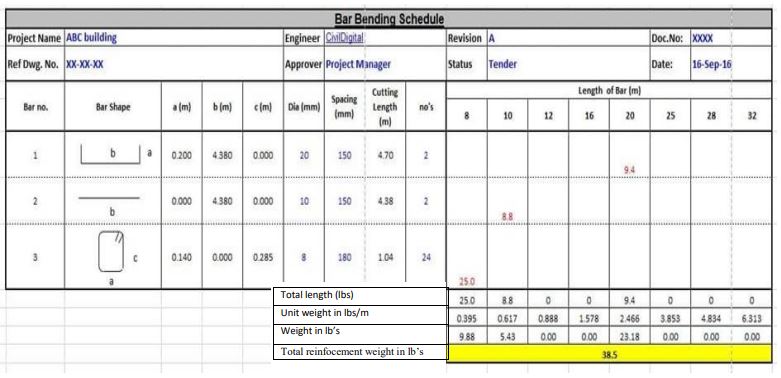

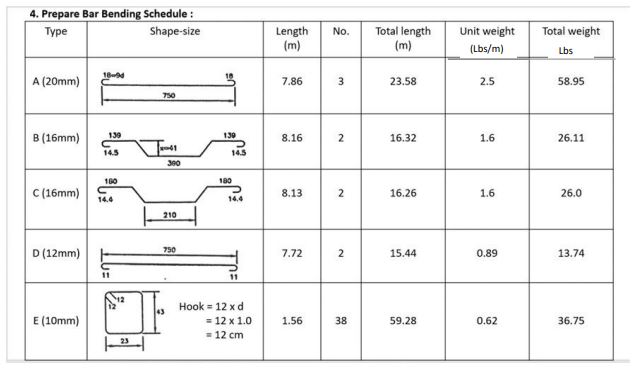

Bar Bending Schedule:

A bar bending schedule is a time-based scheduling technique that may link the requirements of different lengths and sizes of bars in the assembly. The plan is known to all the stakeholders involved in the bar bending process and can be arranged according to their requirements during construction. The bar bending schedule is a prerequisite for the design of a staircase. It gives a detailed list of the required length and shape of bars to be manufactured beforehand. The schedule may also include the layout of the required base number and its layout as needed. Bar bending schedules can be prepared reasonably, allowing the implementer to avoid unnecessary costs and benefits. Bar bending is a great way to reduce construction costs. The industry’s special machines are designed to meet the exacting demands of metalworks quality control engineers. They will use bar bending to repeatedly test each piece of metal and ensure it meets their strict standards.

We can make a bar bending schedule according to the customer’s request for different lengths and sizes of the bars. You can get your custom-made bent plate scheduled by us. The bar bending schedule includes the schedule for shear walls, seismic walls, post-tensioned frames, columns, and much more. The requirement of different lengths and sizes of bars may be known and can be arranged and bent up during construction. Bend-Up Bar Schedules monitor the need for different lengths and cross-sections of bars. This helps in understanding the requirement of various lengths and sizes of a bar during construction. The bar bending schedule is an essential part of any construction project that needs to be prepared in advance. Site condition and other requirements of the specific project determined by the engineers, architects, and other technical staff ensure that all work will be performed on schedule and budget.

A schedule for the production of steel bars in the bending shop can be made according to any number of factors, such as the size and length of the required bars. The figures are calculated based on kiln temperature, which is mainly influenced by: the width of a workbench and its position; heat increased from heaters in the shape of columns with horizontal and vertical walls where they can open in several squares, located in turn around the bar-making machine; effective efficiency of inductive coils that generate electric current using magnetic force reading plate connected to a sensor measuring temperature above which high-power element.