Table of Contents

Air compressors are critical tools for several industries, like automotive, building, and production. Like any mechanical devices, air compressors call for normal maintenance and occasional replacement of elements to assure they proceed to purpose at their ideal. In this report, we’ll examine the best 5 most widespread air compressor elements that want substitute and how to exchange them.

Air Filter

The air filter is an important part of an air compressor mainly because it stops filth, dust, and debris from moving into the compressor’s engine. More than time, air filters grow to be clogged and need to be replaced to preserve proper airflow and stop injury to the motor. To substitute an air filter, initially, track down it on the compressor’s motor. Eliminate the aged filter and insert the new a person, building confident it matches snugly and securely.

Pressure Switch

The strain switch is dependable for turning the compressor on and off at particular force details. If the swap fails, the compressor may well not change on or off effectively, leading to inefficient operation or damage to the compressor. To exchange a force switch, first, change off the compressor and disconnect the ability resource. Find the pressure swap and get rid of the wires and tubing hooked up to it. Then, unscrew the previous change and put in the new 1 in its position. Reconnect the wires and tubing and change the compressor back on.

Belts

Belts are applied to transfer electrical power from the motor to the compressor’s pump. More than time, belts can turn out to be worn or harmed, resulting in diminished efficiency or full failure of the compressor. To replace a belt, initial, identify the belt on the compressor’s motor. Loosen the stress on the aged belt and remove it. Then, put in the new belt and adjust the tension to the manufacturer’s technical specs.

Regulator

The regulator controls the pressure of the compressed air that is unveiled from the compressor. If the regulator fails, the air strain could be far too superior or far too very low, ensuing in inefficient procedure or problems to the compressor. To change a regulator, first, switch off the compressor and disconnect the power source. Identify the regulator and get rid of the screws keeping it in position. Install the new regulator in its position and secure it with screws. Reconnect the energy source and turn the compressor back again on.

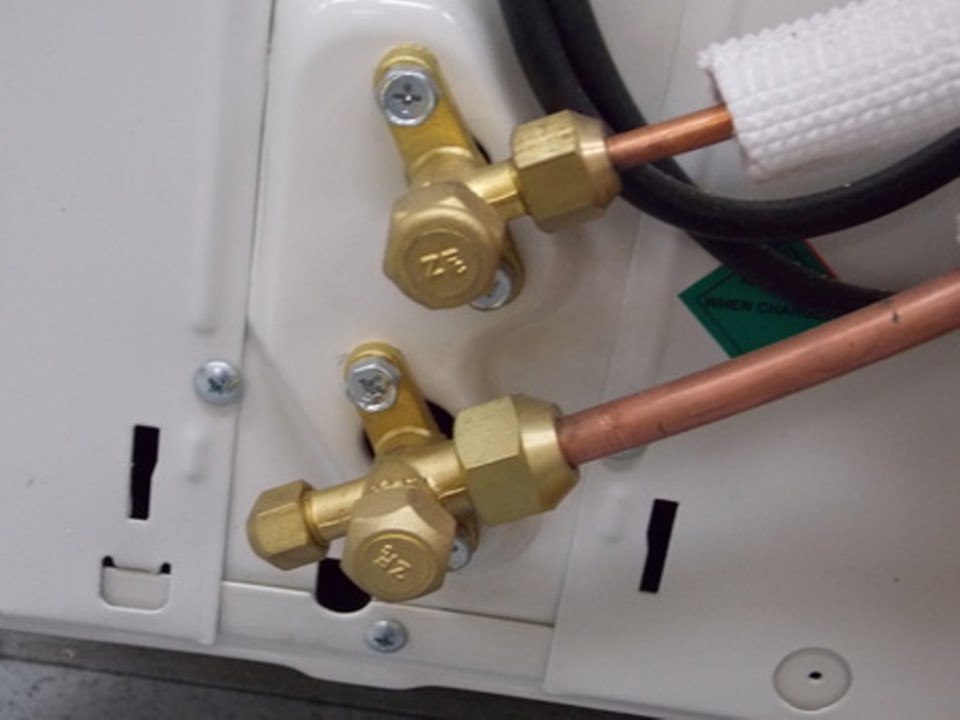

Valves

Valves are utilized to command the circulation of air into and out of the compressor’s tank. More than time, valves can grow to be ruined or worn, resulting in leaks or inefficient operation. To exchange a valve, initially, identify it on the compressor’s engine. Remove the aged valve and install the new one in its spot. Make guaranteed the valve is securely tightened to avert leaks.

In conclusion, air compressors are important applications for a lot of industries and need normal maintenance and occasional substitution of elements to make certain they keep on to perform at their best. The top 5 most popular air compressor components that need replacement consist of the air filter, strain change, belts, regulator, and valves. Even though some components might have to have qualified installation, a lot of can be replaced by the user with the suitable instruments and understanding. By effectively preserving and replacing these components, you can lengthen the lifestyle of your air compressor and make sure it proceeds to perform at its greatest.