University ETH Zürich – Zürich, Switzerland – Researchers at ETH Zurich used a prototype autonomous excavator known as HEAP internally to construct a dry stone wall that was approximately 65 meters long and 6 meters high. The excavator is equipped with combined Lidar, IMU, GNSS and other joint sensing programs and demonstrated construction of a dry laid boulder stone wall which is integrated within a landscape and park that was independently excavated and digitally planned.

The group of researchers comprised the Chair of Landscape Architecture, the Robotics Systems Lab, the Vision for Robotics Lab, and Gramazio Kohler Research. As a component of the National Center of Competence in Research for Digital Fabrication (NCCR dfab), they have put forth the program and this cutting-edge design application.

Robotic Systems Lab studies the creation of intelligent devices capable of functioning in harsh and difficult conditions. The research encompasses new control and optimization algorithms for movement and manipulation, creative designs for greater system mobility and versatility, and unique actuation methods for advanced dynamic interaction—with a particular focus on robots with arms and legs. The group aims to enhance the capabilities and self-sufficiency of intricate robotic systems to enable their application in diverse real-world contexts by drawing inspiration from both people and animals in our pursuit of ingenious solutions.

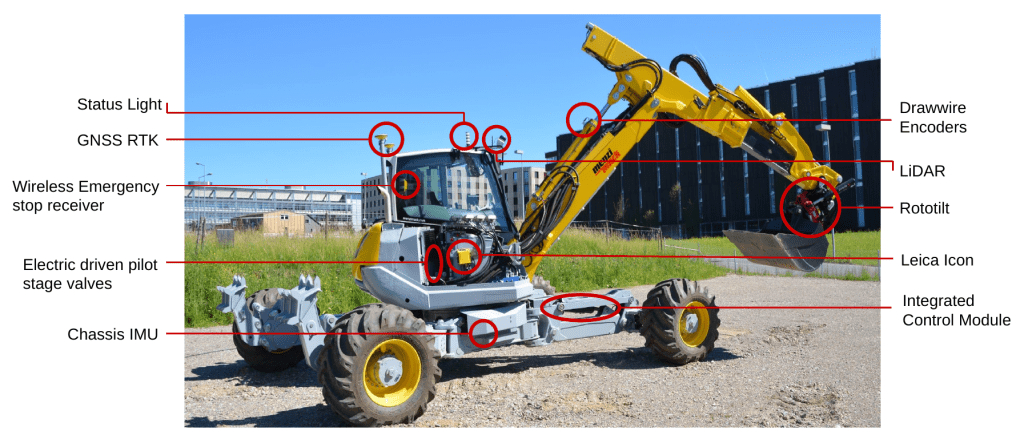

A modified Menzi Much M545 wheeled spider excavator with a clam-shell bucket and programmatic algorithm pick and place multi-sensory system is shown in front miscellaneous stones while it picks and places of dry stack boulders to place in a dry laid wall on construction test bed site.

The excavator can locate existing building materials and stones for the wall’s construction and create an 3D map autonomously of the construction site using sensors. With the use of specially made apparatus and machine vision techniques, the excavator can locate and seize big stones in its immediate surroundings.

Capable of registering their center of gravity and approximate weight. The excavator performs the task itself by positioning the stones in the designated locations after an algorithm has determined each stone’s ideal placement.

Approximately the same number of stones that one delivery might supply, the autonomous machine can place 20 to 30 stones in a single consignment.

A programmatic algorithmic robotic excavator with feeder is shown in front of dry stack boulder wall on construction test bed site.

A programmatic algorithmic robotic excavator with feeder is shown in front of dry stack boulder wall on construction test bed site.

Robotics Autonomy Construction Equipment

Robotics Autonomy Construction Equipment

HEAP must be able to navigate independently in order to complete tasks such as landscaping, item aggregation, and task through autonomous forestry through earth moving. Their research has been working on algorithms for global and local navigation in difficult terrain by use of the fact that the excavator is a walking excavator, which allows it to handle uneven terrain, gaps, and large steps.

The complete published report and demo can be found below: